Groundwork is the unsung hero of any construction project. Before a single brick is laid or steel frame erected, the real work begins on the ground. It covers everything from clearing the site and digging trenches to installing vital drainage and pouring concrete foundations.

Put simply, groundwork is the bedrock of a safe, stable, and long-lasting building.

Understanding The Role Of Groundwork In Construction

Think of building a house like baking a cake. You wouldn’t just pour the mixture onto any old surface; you’d prepare the tin first. Groundwork is exactly that—the essential preparation that gives the final structure a solid and level base to rest on for its entire lifespan.

Without this crucial first stage, even the best-designed building is at risk. Problems like subsidence, structural cracks, and poor drainage often start with shortcuts taken during the groundwork phase. It’s far more than just digging holes; it’s a precise engineering process that sets the stage for everything that follows. That’s why getting it right from the start is so important.

To give you a clearer picture, the core stages of groundwork are summarised below.

The Core Components of Construction Groundwork

This table breaks down the essential stages in a typical groundwork project, from initial site prep to laying the foundations.

| Stage | Key Activities | Purpose |

|---|---|---|

| Site Preparation and Clearance | Removing vegetation, debris, old structures, and topsoil. | Creates a clean, safe, and accessible area for construction to begin. |

| Excavation and Earthworks | Digging trenches, levelling the ground, and creating space for foundations, basements, or services. | Shapes the land according to the building’s specific engineering requirements. |

| Foundation Construction | Pouring concrete footings, slabs, or installing piles. | Creates the solid base that will support the entire weight of the new building. |

| Drainage and Utilities Installation | Laying underground pipes and cables for water, gas, electricity, and sewerage systems. | Ensures all essential services are correctly routed and connected before the main build. |

Each of these stages requires careful planning and execution to ensure the project starts on the right foot.

A fundamental part of many groundwork projects is the proper management and disposal of soil excavated during the earthworks phase.

Groundwork forms the bedrock of every construction project in the UK. This initial phase, encompassing site clearance, excavation, foundation laying, and drainage installation, is where companies like Aylsham Plant Solutions excel with their fleet of modern excavators and dozers tailored for Norfolk and Suffolk sites.

With the construction industry gearing up for significant growth, the demand for precise, efficient earthmoving has never been higher. The Construction Product Association forecasts a 2.5% output rise in 2025 and 3.8% in 2026. This growth is largely driven by new housing targets that will rely heavily on modern groundworks methods to succeed.

The Five Key Stages of a Groundwork Project

Every successful build starts from the ground up. It all follows a logical, carefully planned sequence. When you break it down, groundwork is a journey in five key stages, turning an untouched plot into a perfectly prepared, build-ready site. Each phase builds directly on the last, ensuring the final structure is safe, stable, and built to last.

The whole process kicks off long before the first scoop of earth is moved. It starts with getting to know the land inside and out.

Stage 1: Surveying and Site Investigation

First things first, you need a detailed map. Surveyors use advanced tools like GPS and laser scanners to measure boundaries, levels, and the natural contours of the land. This data is the blueprint for everything that follows. It tells the team exactly where the new structure will sit and how the ground needs to be shaped.

At the same time, geotechnical engineers find out what’s going on beneath the surface. They analyse soil composition, check for stability, and work out where the water table is. This information is vital for designing the right type of foundations and avoiding future problems like subsidence.

Stage 2: Site Clearance and Preparation

Once the surveys are done and the plans are in place, the physical work can begin. This stage is all about clearing the project’s entire footprint to create a clean slate. It’s far more than just a quick tidy-up; it’s a critical preparation phase.

Typical jobs here include:

- Removing Vegetation: Clearing away trees, shrubs, and bushes.

- Demolishing Obstructions: Taking down any old buildings or unwanted structures.

- Clearing Debris: Getting rid of rubble, rocks, and anything else in the way.

- Stripping Topsoil: The nutrient-rich topsoil is carefully scraped back and usually stored on-site to be used later for landscaping.

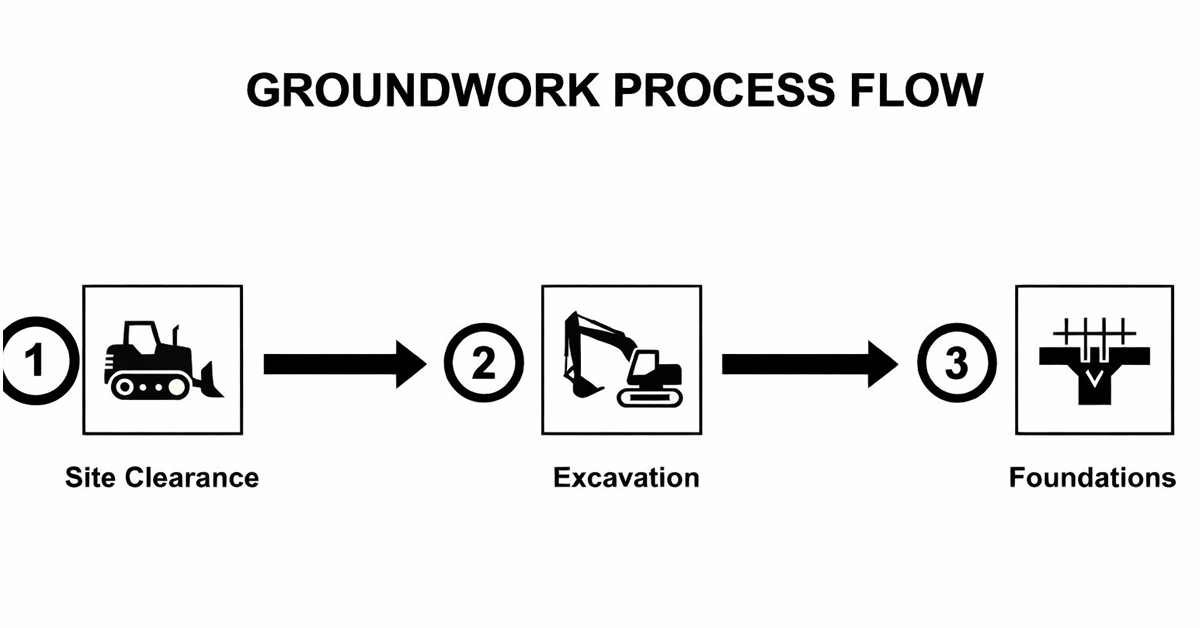

This simple flow diagram shows how the project moves from a clear site to solid foundations.

As you can see, each step provides the platform for the next, ensuring a systematic and stable build from the very start.

Stage 3: Earthworks and Excavation

With a clear site, the next job is to shape the land according to the engineering plans. This phase, known as earthworks, involves moving large quantities of soil to get the right levels for the building, access roads, and car parks.

Excavation follows straight after. This is where trenches are precisely dug for the foundations and any underground structures like basements. The accuracy of the initial survey really pays off here, making sure every trench is in exactly the right place and at the perfect depth.

Stage 4: Utilities and Drainage Installation

Before any concrete is poured for the foundations, all the essential underground services must be installed. This means laying pipes for foul and surface water drainage. It also involves putting in conduits for electricity, gas, water, and data cables.

Getting this stage right is absolutely crucial. A well-designed drainage system prevents waterlogging and protects the building’s foundations from moisture damage. Trying to retrofit these services later is incredibly difficult and expensive, so precision here is essential.

Stage 5: Foundation Construction

The final stage of groundwork is building the foundations themselves. This is when the structure’s base is created. This part is responsible for transferring the entire weight of the building safely into the ground. Depending on the soil conditions and building design, this could involve different types of foundations, from traditional strip footings to a reinforced concrete raft.

In the UK construction landscape, getting groundwork right has a huge impact on timelines and budgets. With government initiatives like £2 billion for social housing and £13 billion for infrastructure over the next five years, the pressure is on. For local authorities in Norfolk and Suffolk, these projects all start with efficient site preparation. This makes professional groundworks essential for taking advantage of the projected 15-20% output growth in the coming years. To get a better feel for these trends, you can explore detailed insights on the UK construction outlook.

Essential Plant and Machinery for Groundwork

Successful groundwork relies on a specialist fleet of heavy machinery. Think of it like a well-drilled team where each piece of equipment has a specific job. Together, they turn a raw patch of land into a construction-ready site. The right plant makes every stage, from clearing the ground to digging foundations, safer, faster, and more precise.

Choosing the correct machine for the job is critical. A nimble mini digger is perfect for a tight residential garden in Norwich, but it would be out of its depth on a large commercial project in Suffolk. That kind of job demands the raw power of a 20-tonne excavator to shift thousands of cubic metres of soil without delays. This is where understanding what is groundwork in construction translates into practical, on-the-ground decisions.

The Workhorses of the Site

Certain machines are staples on almost every groundwork project. They are the core of the fleet, each handling a distinct but vital task. Getting this mix right is the key to a smooth workflow, preventing bottlenecks that cost time and money.

Here’s a quick rundown of the most common plant you’ll see:

- Excavators: These are the ultimate all-rounders. You’ll find them digging trenches, carving out foundations, and moving huge volumes of earth. They come in all sizes, from agile 1.5-tonne models to heavy-duty giants.

- Dumpers: Just as the name suggests, dumpers are essential for moving loose materials like soil, hardcore, and aggregates around the site. They work alongside excavators to keep the whole operation flowing.

- Rollers: Once new material like hardcore is laid for a sub-base, rollers come in to compact it. This creates a solid, stable, and level surface—crucial for preventing the ground from settling later on.

- Dozers: For large-scale levelling and stripping a site back to bare earth, a bulldozer is unbeatable. Its powerful blade can push massive quantities of soil, quickly reshaping the landscape to match the project’s plans.

Matching the Right Plant to the Groundwork Task

Knowing which machine to use for which job is part of the groundwork expertise we bring to every project. Here’s a simple guide to how our Aylsham Plant Solutions fleet matches up with common tasks.

| Groundwork Task | Recommended Aylsham Plant | Why It’s the Right Choice |

|---|---|---|

| Site Clearance & Stripping | Bulldozer, 13-Tonne Excavator | A dozer quickly removes topsoil. The excavator handles deeper-rooted obstacles and loads waste into dumpers. |

| Trenching for Utilities | 1.5 to 6-Tonne Excavator | Smaller excavators offer precision and can operate in confined spaces, digging clean trenches without disturbing the wider area. |

| Bulk Earthmoving | 20-Tonne Excavator, 14-Tonne Dumper | This combination offers maximum efficiency. The large excavator has the power to dig and load fast, while the dumper moves material away. |

| Sub-base Compaction | 80cm or 120cm Roller | Rollers provide the necessary weight and vibration to create a solid, uniformly compacted base for roads, paths, and foundations. |

| Foundation Excavation | 6 to 13-Tonne Excavator | These mid-size machines balance power with precision, ideal for digging strip or pad foundations to the exact required depth. |

This combination of specialist machinery ensures every stage of the groundwork is handled efficiently and correctly, setting the project up for success.

Specialised Equipment for Modern Groundworks

Beyond the core fleet, today’s groundwork projects often rely on more specialised machinery to boost efficiency. These tools help contractors hit tight deadlines and comply with environmental standards, adding real value.

One of the biggest advances we’ve seen is the use of on-site crushing and screening plant. These machines take excavated rubble and old concrete and recycle it directly into usable hardcore. This doesn’t just save a huge amount on material costs; it also dramatically cuts down on lorry movements and the amount of waste sent to landfill.

This commitment to efficiency carries right through to laying the foundations. To see how specialist plant supports this final, crucial step, you can explore our detailed guide on foundation work equipment.

Of course, protecting this valuable machinery is a top priority. To safeguard your equipment and materials, bringing in construction site security guards can prevent theft and vandalism, keeping your project secure and on schedule.

Navigating Regulations and Site Challenges in East Anglia

Every construction project has its hurdles. In East Anglia, the ground itself can present a unique set of challenges. Understanding the specific conditions and regulations in Norfolk and Suffolk isn’t just good practice—it’s essential for keeping your project on time and on budget.

Working in this part of the country means you have to be ready for all sorts of soil types. The heavy clays common across Norfolk, for example, can swell when wet and shrink when dry. If your foundations aren’t designed to handle that movement, you’re asking for trouble. In other areas, you might find soft peat or loose, sandy soils, which demand different strategies for stabilisation.

Ignoring these local quirks is a recipe for expensive problems. That’s why a thorough site investigation is the first step for any groundwork in East Anglia.

Dealing with Local Ground Conditions

Before any work starts, you need to know exactly what you’re dealing with. A geotechnical survey is the tool for the job. It identifies the soil type, its load-bearing capacity, and where the water table sits. This information directly shapes the design of your foundations and drainage system.

For instance, building on reactive clay might mean you need deeper foundations or a reinforced raft design. On the other hand, a high water table, especially near the Fens or the Broads, demands a robust plan to keep excavations dry.

An experienced local contractor understands these issues. They know which areas are prone to flooding, where you’ll find chalk that makes digging difficult, and how to adapt their methods to your specific site. This insight prevents nasty surprises.

Adhering to Local and National Rules

Beyond the soil, every groundwork project is governed by a web of regulations. Sorting out planning permission with councils like Norfolk County Council or Suffolk County Council is just the start. You also have to follow strict rules from national bodies.

Here are the key players you’ll be dealing with:

- Planning Permissions: This is your legal green light from the local authority. They check that your project fits with local development plans and building standards.

- Building Regulations: These are the technical rules covering everything from foundation depth to structural stability. They ensure the final building is safe and solid.

- Health and Safety Executive (HSE): The HSE enforces workplace safety. Groundwork sites are full of hazards, so a comprehensive health and safety plan is crucial for protecting your team.

- Environment Agency: If your work is near a river or in a sensitive area, the Environment Agency has strict rules on preventing pollution and managing waste.

Successfully juggling these challenges shows why it pays to partner with a groundwork specialist with deep roots in East Anglia. A contractor with local knowledge isn’t just a supplier; they’re your best asset for a smooth and successful project.

Why Professional Groundwork Is a Smart Investment

Trying to cut corners on groundwork is one of the biggest gambles in construction. It might seem like a saving upfront, but poor groundwork can lead to future disasters that will cost a fortune to fix.

Think of it this way: professional groundwork isn’t just a budget item. It’s the most important insurance policy you can buy for your build, protecting the long-term value and safety of the entire structure.

Preventing Costly Future Failures

Nearly all of the most serious building problems—subsidence, damp, and major structural cracks—can be traced back to mistakes made at the very beginning. When foundations are laid on improperly compacted soil or drainage systems are poorly planned, the consequences are always severe.

These issues often appear slowly, showing up as cracks in walls or shifting floors. The cost to put these things right years down the line can be huge, easily dwarfing any initial “savings.”

Investing in expert groundwork from day one is the only way to guarantee the stability and longevity of your building. A quality start ensures your project stands on a solid, reliable, and professionally engineered base.

Keeping Your Project on Time and on Budget

A reputable groundwork contractor does more than just dig trenches; they are masters of logistics. They ensure the right machinery is on-site when needed, that materials are delivered efficiently, and that every task is completed in the correct sequence. This coordination stops small delays from spiralling into costly overruns.

By getting it right the first time, professionals eliminate the unexpected expenses that plague badly planned projects. They navigate complex legal standards and ensure the site is safe and compliant, preventing potential fines or work stoppages.

A smooth groundwork phase sets an efficient tone for the entire build. It’s why so many groundwork contractors rely on professional plant hire to maintain momentum. Ultimately, a quality start isn’t just a good idea—it’s the smartest investment you can make.

Choosing Your Groundwork Contractor in Norfolk and Suffolk

Finding the right team for your groundwork is one of the most important early decisions you’ll make. A reliable contractor in Norfolk and Suffolk won’t just deliver a high-quality job; they’ll give you confidence that the very base of your build is solid and secure.

When you’re checking potential partners, their experience is everything. Ask to see a portfolio of similar local projects and speak to a few previous clients. A proven track record is the best evidence they understand the unique challenges of East Anglian soil and local regulations. That kind of knowledge is priceless for keeping a project running smoothly.

Key Questions to Ask

Before you sign any contracts, you need clear answers on a few key points. A professional firm will expect these questions and have transparent answers ready.

- Fleet and Equipment: Do they own a modern, well-maintained fleet? Having the right machinery on hand is essential for efficiency. You can learn more about the difference a professional fleet makes in our guide to operated plant hire.

- Insurance and Accreditations: Are they fully insured with both public and employer’s liability cover? Ask to see their industry accreditations – these are a clear sign of their commitment to professional standards.

- Health and Safety: What’s their safety record like? They should be able to provide comprehensive risk assessments and method statements (RAMS) for your project without hesitation.

Choosing a contractor is about far more than just picking the cheapest quote. It’s about finding a partner you can genuinely trust. Verifying their credentials, checking their equipment, and confirming their safety protocols are essential steps to protect your investment.

Your Groundwork Questions Answered

If you’re planning a project, you probably have a few questions about the groundwork phase. Here are some of the most common queries we hear from clients.

How Long Does The Groundwork Phase Typically Take?

This really depends on the scale of the job. For a small residential extension on good ground, it might only take a week or two. A large commercial development, on the other hand, could easily take several months.

The timeline is often extended by variables. A complex drainage system, difficult clay soil, or a site that needs extensive clearance will all add time. The only way to get a reliable schedule is to have a professional contractor complete a full site survey first.

What Is The Biggest Cause Of Delays In Groundwork?

More often than not, delays come down to two things: unforeseen ground conditions and bad weather. Discovering hidden pipes, unstable soil, or a high water table during the dig can bring work to a halt.

Likewise, persistent heavy rain can turn a site into a muddy, unsafe, and unworkable environment. The best way to guard against these issues is to invest in thorough initial surveys and hire an experienced local contractor who knows East Anglia’s geology.

Can I Save Money By Doing Some Groundwork Myself?

While it’s tempting to tackle some of the work yourself on smaller jobs, it’s generally not a good idea. Groundwork is a specialist trade that relies on heavy machinery, an understanding of soil mechanics, and strict health and safety rules.

A small mistake at this stage can lead to huge structural problems and costly repair bills down the line. Hiring a professional firm gives you peace of mind that the job is done right, safely, and efficiently from the start – a far better long-term investment.

For expert advice and a dependable fleet for your next project in Norfolk or Suffolk, trust Aylsham Plant Solutions. Find out how our groundwork services can provide the solid start your project deserves.

Related Posts