Think of ready mix concrete as a professionally made meal delivered straight to your site. Instead of buying and mixing all the ingredients yourself, this specially prepared concrete is batched at a plant to exact specifications. This gives you guaranteed strength and consistency every time. It removes the guesswork and expensive errors that can happen with on-site mixing.

Understanding Ready Mix Concrete

Ready mix concrete is a game-changer for construction projects, big or small. It is a precise blend of cement, aggregates (like sand and gravel), and water. Everything is mixed in the controlled environment of a batching plant. This process ensures every cubic metre meets strict quality standards.

Unlike traditional site mixing, where materials are often combined by eye, the ready mix approach takes human error out of the equation. Each batch is computer-controlled. This makes sure the ratios are perfect for the strength you need.

This level of precision is vital. You need to be confident in your materials, whether you’re laying a simple shed base, a new house extension foundation, or a large commercial slab.

Why Quality Control Matters

The secret to reliable ready mix concrete is the batching plant. These certified facilities follow rigorous UK standards. They test raw materials and final mixes to make sure they are correct. This quality assurance gives you peace of mind that site-mixed concrete cannot match.

The real-world benefits are clear:

- Consistent Strength: Every lorry delivers a product that will cure to the exact strength you ordered. There are no weak spots or surprises.

- Reduced Labour Costs: Your team can focus on placing and finishing the concrete, not on the hard work of mixing it.

- Minimal On-Site Waste: You order the exact amount needed. This means no piles of unused sand and gravel are left on your site.

- Time Efficiency: The concrete arrives ready to pour. This can save hours or even days on your project timeline.

A successful pour isn’t just about the quality of the concrete; it’s about the quality of the preparation. A well-prepared site is the foundation for a flawless finish, preventing delays and ensuring the material performs exactly as it should.

The Role of Site Preparation

The success of your concrete pour is decided long before the mixer lorry arrives. Proper site preparation is essential. It sets the stage for a smooth, efficient delivery. This is where professional plant and machinery play a critical part.

Using machinery like excavators to dig accurate footings and dumpers to clear spoil ensures your foundations are spot on. Compacting the sub-base with rollers creates a stable, level surface. This prevents future cracking or subsidence.

A well-prepared site with clear, stable access for a heavy concrete lorry is the first step to a durable result. It’s how you make sure your project starts on solid ground.

Understanding Concrete Grades, Mixes and Slump

Ordering the right ready mix concrete does not need to be a guessing game. By understanding a few key terms, you can confidently choose the perfect mix for your job. This ensures it has the right strength and workability from day one. The three most important elements are the concrete grade, its slump, and any specialist additives.

Think of these as the core parts of a concrete ‘recipe’. Getting them right is vital for the long-term performance of everything from a garden path to a structural foundation. Let’s break down what each one means in practical terms.

Decoding Concrete Grades

The grade of concrete is all about its compressive strength after it has fully cured over 28 days. You will see it written as the letter ‘C’ followed by a number, like C20 or C35. That number tells you the minimum strength the concrete can handle, measured in newtons per square millimetre (N/mm²).

It is like picking the right tool for the job. A higher number means stronger concrete. This is essential for structures that need to bear serious weight.

To help you, here is a quick-reference table. It shows common concrete grades and where you will typically find them used on UK projects.

Common Ready Mix Concrete Grades and Their Uses

| Concrete Grade | Compressive Strength (N/mm²) | Common Applications |

|---|---|---|

| C10 / GEN1 | 10 | Non-structural fill, blinding, and kerb backing. |

| C20 / GEN3 | 20 | Domestic projects like shed bases, patios, and garden paths. |

| C25 / PAV1 | 25 | Pavements, domestic driveways, and garage floors. |

| C30 & C35 | 30 – 35 | Commercial-grade mixes for house foundations and structural slabs. |

| C40+ | 40+ | Heavy-duty industrial uses like structural beams and columns. |

As you can see, choosing the right grade is the first step. If an engineer or architect has specified your project, they will have already figured out the exact grade required.

The consistency of your ready mix concrete, known as its ‘slump’, is just as important as its strength. It dictates how easily the concrete will flow from the mixer and fill your formwork, directly impacting the final quality of the finish.

Understanding Slump and Workability

If grade is about strength, then slump is all about consistency. Imagine making cake batter. Sometimes you need a thick, stiff mix, while other times a runnier one is better. Slump is the construction world’s equivalent. It measures how workable or fluid the wet concrete is.

A ‘slump test’ is a simple on-site check to verify this. A higher slump means the concrete is more fluid and will flow easily. This is ideal for filling complex shuttering or when using a concrete pump. A lower slump means a stiffer mix, perfect for creating slopes or pouring directly from the chute.

For a deeper dive into this, you can check out our guide on how to calculate the perfect concrete mix for your needs.

The Role of Specialist Additives

Modern ready mix concrete is a clever product. We can fine-tune it with special additives at the plant to change its performance for specific conditions.

Here are some useful additives for projects in the UK:

- Air-Entraining Admixtures: These add billions of tiny air bubbles to the mix. This is vital for any external concrete in the UK. It gives water space to expand when it freezes, preventing frost damage during harsh winters.

- Plasticisers (Water Reducers): These chemicals increase the slump and workability of the concrete without adding more water. Adding more water would weaken the final product. They are essential for a fluid mix that can be pumped easily over long distances.

- Retarders: As the name suggests, these slow down the curing process. They are useful on hot summer days. They give your team more time to place and finish the concrete before it starts to set.

By specifying the right grade, slump, and additives, you can be sure the ready mix concrete delivered to your site is perfectly suited for your project.

Ready Mix Concrete Versus Site Mixing

Deciding between ready mix concrete and mixing it yourself is a key choice. It can shape your project’s efficiency, quality, and final cost. For most modern construction jobs, from a simple extension foundation to a large commercial slab, the advantages of professionally batched concrete are clear. It is a choice between guaranteed quality and the unpredictable nature of on-site work.

Think of it like this: ready mix is a professionally catered meal, delivered hot and ready to serve. Site mixing is like cooking from scratch on location. You are responsible for sourcing, measuring, and combining every ingredient correctly. Cooking yourself works for a small meal, but for a large event, the quality of catering is unbeatable.

The same logic applies to concrete. Ready mix concrete arrives as a finished product, engineered to a precise specification. This process removes risks and responsibilities from your team. It allows them to focus on placement and finishing.

The Case for Quality and Consistency

The biggest advantage of ready mix concrete is quality control. In a certified plant, every component is measured by weight using calibrated equipment. This ensures the water-to-cement ratio is perfect every time. This computer-controlled process guarantees that every cubic metre delivered will meet the specified strength.

Site mixing, even with experienced workers, can lead to errors. Shovel-based measurements are inaccurate. Small variations in the amount of water can reduce the final strength of the concrete.

This is where the difference becomes critical. For a garden wall, minor inconsistencies might be okay. But for a load-bearing foundation, you cannot afford to gamble on the material’s performance.

Efficiency and Labour on Site

Time and labour are two of the biggest costs on any construction site. Choosing ready mix concrete has a direct, positive impact on both.

- Reduced Labour: Site mixing is a labour-intensive job. It requires workers to handle heavy bags of cement and move tonnes of aggregate. With a ready mix delivery, your team is free to prepare for the pour and manage placement. This is a far more efficient use of their time.

- Faster Timelines: A concrete mixer lorry can discharge several cubic metres of concrete in minutes. Mixing that same volume on-site with a small mixer would take a team hours. This would push your project timeline back and increase labour costs.

The UK’s ready-mixed concrete sector is undergoing a fundamental transformation driven by sustainability imperatives and technological innovation. The government’s Net Zero 2050 ambition has catalysed growing demand for low-carbon and recycled concrete solutions. Ready-mixed concrete’s inherent advantages—effectiveness, speed of deployment, and waste reduction compared to site-mixed alternatives—make it increasingly attractive to developers and contractors. You can explore more about these industry trends on Spherical Insights.

When Could Site Mixing Make Sense?

Despite the clear benefits of ready mix, there are a few situations where mixing on-site might still be an option. These are typically limited to very small jobs or remote locations.

For instance, if you only need a barrow-load of concrete for a single fence post, ordering a full delivery would not be practical. Likewise, if your site has difficult access for a heavy mixer lorry, transporting the raw materials yourself might be the only option.

However, for any project needing a cubic metre or more, the choice is clear. The guaranteed quality, reduced labour, and huge time savings of ready mix almost always deliver a more professional and cost-effective result.

The Logistics of Ordering and Delivery

Getting ready mix concrete from the plant to your site smoothly is a critical part of any pour. It is a straightforward process if you do your homework. A small mistake in logistics can lead to costly delays or wasted material. It all starts with one crucial calculation before you pick up the phone.

The most common mistake is getting the volume wrong. Ordering too little is a major problem. Pouring fresh concrete onto a batch that has started to cure creates a weak ‘cold joint’. This can compromise the whole structure. Precision is key.

Calculating Your Required Volume

The formula is simple: Length x Width x Depth = Volume in cubic metres (m³).

Use a tape measure and be precise with your formwork. Make sure all your measurements are in metres. For example, a rectangular slab that is 5 metres long, 4 metres wide, and 0.15 metres (150mm) deep needs 5 x 4 x 0.15 = 3m³ of concrete. For complex shapes, break them down into smaller rectangles and add the totals together.

Once you have your base number, always add a contingency of 5% to 10%. This buffer is your safety net. It covers variations in ground level, spillage, or concrete left in the lorry’s chute. It is cheaper to have a bit too much than to order a second lorry.

To make this step easier, check out our instructions on how to figure out how much concrete you need for your project.

Placing Your Order

With your exact volume sorted, you can contact your supplier. Be ready to give them a few key details to ensure the right mix arrives at the right time.

You will need to specify:

- The Concrete Grade: For example, C25 for a domestic driveway or C35 for foundations.

- Any Additives: Let them know if you need air-entrainment for frost protection or plasticisers for a pump mix.

- The Delivery Address: A full address and postcode, plus any specific instructions for finding the site entrance.

- Your Required Date and Time: Give as much notice as you can, ideally at least 48 hours.

- The Delivery Method: Tell them if you will take it straight from the chute or if you have arranged for a concrete pump.

Clear communication prevents mix-ups. It means the plant can schedule your delivery without a problem.

Preparing for the Delivery Lorry

A fully loaded concrete mixer is a heavy piece of plant, weighing up to 32 tonnes. It needs safe, solid ground to get near your pour site. Before delivery day, you must check your site access.

Think about these key points:

- Gateways and Entrances: The vehicle needs a clear opening of at least 3 metres wide.

- Ground Conditions: The lorry cannot drive over soft ground or unstable surfaces. It needs a firm, compacted hardcore base to avoid getting stuck.

- Overhead Obstructions: Look for low-hanging branches or power cables that could get in the way.

- Turning Space: Make sure there is enough room for the lorry to manoeuvre safely and get out after the pour.

A reliable company will adhere to strict regulations, including DOT compliance for trucking companies. This is a good indicator of their commitment to safety on the road and on your site.

Chute vs Pump Delivery

Finally, how will the concrete get from the lorry into your formwork? The two main options are using the lorry’s chute or hiring a concrete pump.

The standard chute on a mixer can usually reach about 3 to 4 metres. If your pour area is within that distance of where the lorry can park, a direct chute delivery is the simplest method.

However, if the pour is at the back of a house or out of reach, you will need to hire a concrete pump. A pump can move concrete quickly over long distances, around obstacles, and up to higher floors. It is an essential tool for any site with restricted access.

On-Site Quality Control and Common Challenges

Once the ready-mix lorry arrives at your site, the job is not over. The focus now shifts to making sure that high-quality product is placed correctly.

A successful pour comes down to a few simple on-site checks and an awareness of common hurdles, especially the unpredictable British weather. Getting this stage right is as important as ordering the correct mix.

A few simple quality checks can give you confidence in the delivery. The most common is the slump test. This is a quick way to verify the concrete’s workability. This check confirms the consistency matches your order, ensuring it is not too stiff or sloppy for the job.

Navigating On-Site Challenges

Even with a perfect mix, conditions on site can cause problems. From weather extremes to human error, being prepared is key to a durable finish. Managing small issues proactively stops them from becoming major headaches.

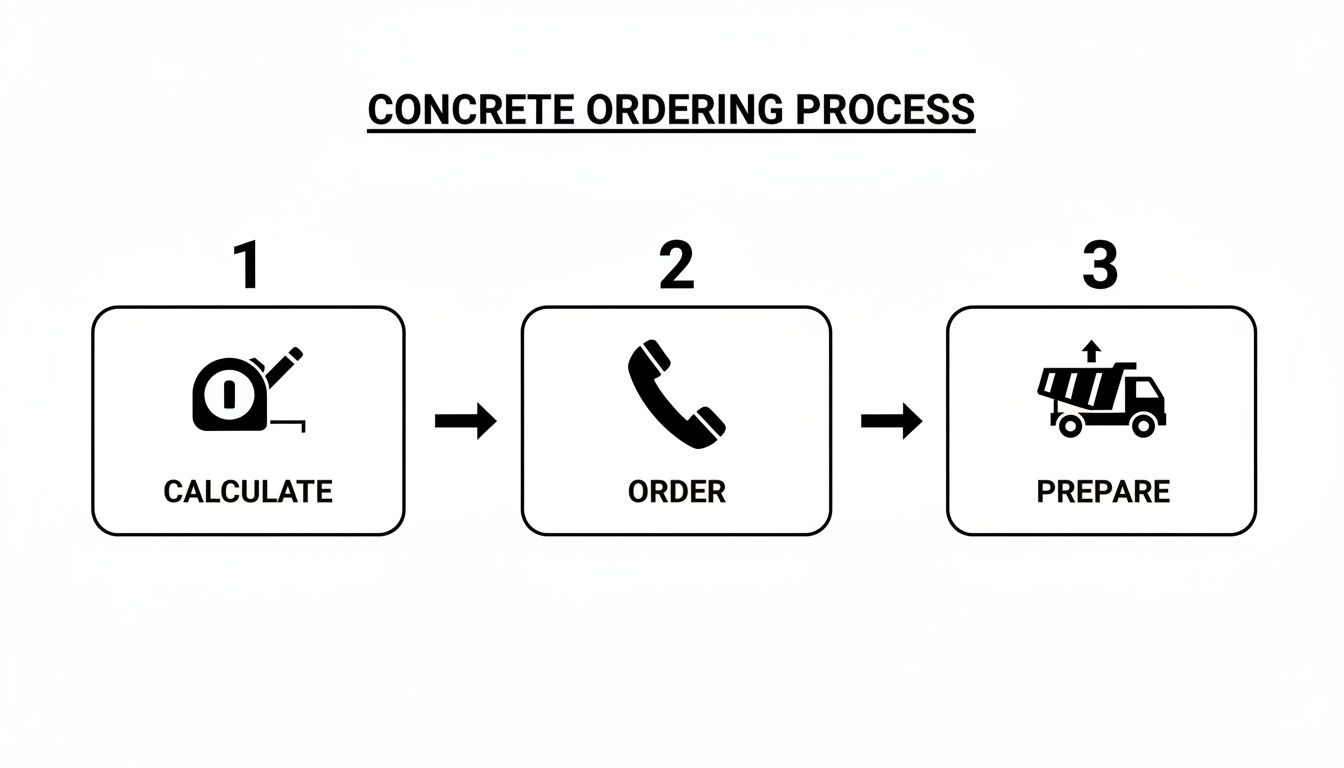

The flowchart below breaks down the simple three-step process for getting your site ready for a concrete delivery.

As you can see, a smooth delivery depends on accurate calculations, clear ordering, and thorough site preparation.

Working with British Weather

We all know the weather is a huge factor in any UK construction project, and concrete is no exception. As a rule, you should avoid pouring if the temperature is below 5°C and falling. Frost can halt the curing process and permanently weaken the concrete. In winter, it is smart to have insulating blankets ready to protect the fresh slab.

Hot and windy days can cause the surface to dry out too quickly. This can lead to shrinkage and cracking. On summer jobs, lightly dampening the sub-base before the pour and covering the finished surface with hessian sheeting helps it cure evenly.

The golden rule on site is to never add extra water to the mix to make it more workable. It might seem like a quick fix, but it throws the critical water-to-cement ratio out of balance, seriously reducing the final strength and durability of your concrete.

Avoiding Common Pouring Defects

Two frequent problems can spoil an otherwise perfect pour: cracking and honeycombing. Here is what to watch for.

- Cracking: This is often caused by the concrete drying too fast or from not having the right joints. Controlled curing and cutting expansion joints in larger slabs are the best ways to prevent it.

- Honeycombing: This leaves rough, stony patches on the surface where the cement paste has not filled the gaps. It is usually down to a mix that is too stiff or has not been compacted properly.

Working with a dependable supplier is vital, especially when the market is unsteady. Recent government data shows volatility in the ready-mixed concrete sector, with an annual demand drop of 9.9%. This proves the need for reliable partners who can adapt to changing demands. You can read more about these construction material trends on the GOV.UK website.

By controlling what you can on-site, you protect your investment and guarantee a high-quality finish, every time.

Preparing Your Site for a Concrete Delivery

The success of a concrete pour is decided long before the mixer lorry arrives at your site. While high-quality ready mix is vital, even the best concrete can be let down by poor ground preparation. This final stage is where everything comes together. It all hinges on professional groundworks and reliable plant hire.

We do not supply the concrete at Aylsham Plant Solutions, but we are experts in creating the perfect foundation for it. Proper site prep prevents costly delays and keeps everyone safe. It is the first step to a durable, high-quality finish. It is all about getting your project ‘concrete-ready’ from the ground up.

Creating a Stable Foundation

The lifespan of any concrete slab depends on what is underneath it. A stable, well-compacted sub-base is non-negotiable. If you skip this, you invite subsidence and cracking later on.

This is where our fleet of plant and machinery comes into its own. We provide the essential equipment to get the job done right:

- Excavators: For digging precise foundations and footings to the exact depth.

- Dumpers: To shift spoil and hardcore efficiently, clearing the area and building up your sub-base.

- Rollers: To achieve the solid compaction needed for a base that will support the concrete for decades.

Getting that ground density right often relies on powerful equipment like compaction rammers. You can find out more about our extensive range of foundation work equipment and see how it supports projects across East Anglia.

Ensuring Safe and Clear Access

A fully loaded concrete mixer is an incredibly heavy vehicle. It needs a safe, clear path to the pour site. Inadequate site access is a common reason a delivery is turned away. Our groundwork services ensure haul roads are established with compacted hardcore. This gives the lorry a solid path that can handle the weight without any problems.

A well-prepared site is your project’s best insurance policy. It guarantees that your investment in quality ready mix concrete isn’t wasted and ensures a smooth, efficient pour that stays on schedule and within budget.

Understanding the bigger picture also helps with planning. The UK ready-mixed concrete industry hit an estimated £3.6 billion in revenue. Despite some dips, forecasts predict strong growth of around 5.91% annually, thanks to government investment in infrastructure. For contractors, keeping an eye on these trends helps anticipate material availability and pricing.

From the first dig to the final roll, having the right machinery on-site is crucial. Get in touch with Aylsham Plant Solutions today to discuss your site preparation needs and ensure your project is set up for success.

Your Top Questions Answered

Getting the logistics right for a concrete pour can feel like a puzzle, but a bit of planning makes all the difference. We get a lot of questions from project managers and builders, so we have put together answers to the most common queries.

Nailing these details means your pour day will run smoothly, saving you headaches, time, and money.

How Much Notice Should I Give for a Ready Mix Delivery?

As a rule of thumb, it is best to give your supplier at least 48 hours’ notice for a standard mix. If you need a large volume or a specialised mix, giving a week’s notice is a safer bet.

But the most important part is this: the biggest mistake we see is booking a concrete delivery before your site is ready.

Make sure your foundations are fully dug, the sub-base is compacted, and you have a clear, stable route for the delivery lorry before you confirm your order. This stops a fully loaded mixer turning up to a site that cannot take it. This can lead to serious waiting time or return charges.

What Happens If I Get the Concrete Quantity Wrong?

Ordering the wrong amount of concrete is a real problem. If you order too little, you are in a tight spot. Trying to join two separate pours creates a ‘cold joint’. This is a structural weak point that can compromise the strength of a slab or foundation.

The best practice is to measure your area carefully, then add a 5% to 10% contingency to your final calculation. This small buffer covers any uneven ground or minor spillage. It is far cheaper than the delay and cost of ordering a second, small top-up load.

If you order too much, you will almost certainly be charged for the return and disposal of the leftover material. If calculating the volume is tricky, ask your supplier about volumetric mixers. These lorries mix the concrete on-site, so you only pay for what you use.

Can I Pour Concrete in Any Weather?

Absolutely not. Weather is a critical factor that affects the quality and final strength of your concrete. You should never pour concrete if the air temperature is below 5°C and falling. When it is that cold, the water in the mix can freeze. This stops the chemical curing process and can permanently weaken the finished product.

Hot, sunny, or windy conditions are just as bad. They can cause the surface to dry out too quickly, leading to shrinkage and cracking. Always check the forecast and have the right protective gear on site, like insulating blankets for cold snaps or hessian sheeting for hot weather.

While we’re focused on getting your site perfectly prepared, starting with the right machinery for the groundworks is the first step to success. For expert advice on plant hire, from excavators to dumpers, speak with the team at Aylsham Plant Solutions. Find out more about how we can support your project at https://aylshamplantsolutions.co.uk.

Related Posts