Getting your concrete mix right is not just a step in the process—it is the foundation of your entire project. The exact ratio of cement, aggregate, sand, and water determines the strength, durability, and success of everything you build.

Getting this wrong is not a small inconvenience. It is a costly mistake that can derail a project quickly.

Why Accurate Concrete Mix Calculation is Essential

On any construction site, a successful job starts long before the first pour. It begins with solid, accurate calculations. A miscalculation in your concrete mix can cause a domino effect of problems, hitting your budget and timeline hard.

Imagine pouring a foundation slab, only to find it fails a strength test. The cost is not just the wasted materials. It includes demolition, removal, and expensive delays while you start over. Meanwhile, the machinery you have hired—from the excavator to the dumper—sits idle while costs mount up.

The Real Cost of Getting It Wrong

A poor mix has consequences that go far beyond the initial pour. Here is what is at stake when the numbers are off:

- Weakened Structure: This is the most serious risk. A weak mix leads to cracking and structural failure. It is a massive safety hazard.

- Wasted Materials and Money: Ordering too much material eats into your profit. Ordering too little brings the project to a halt. With material costs always changing, precision is key.

- Costly Rework and Delays: Tearing out and redoing a bad pour is one of the most frustrating and expensive jobs in construction. It ruins schedules and damages your reputation.

For contractors, a perfect concrete mix is essential for sturdy foundations and efficient site preparation. Nailing your water-cement ratios can slash rework by up to 20%, keeping projects on track and profitable.

The Core Ingredients and Why Ratios Matter

Every concrete mix is a careful balance of four key ingredients: cement, fine aggregate (sand), coarse aggregate (gravel), and water. The ratio of these components determines the concrete’s workability, strength, and durability.

There is no “one-size-fits-all” recipe. The ideal mix depends entirely on what you are building. A garden path has different needs from a heavy-duty industrial floor. Getting that ratio right is a basic principle in all groundwork, from site prep to the final surfacing.

Understanding Common UK Concrete Mix Ratios

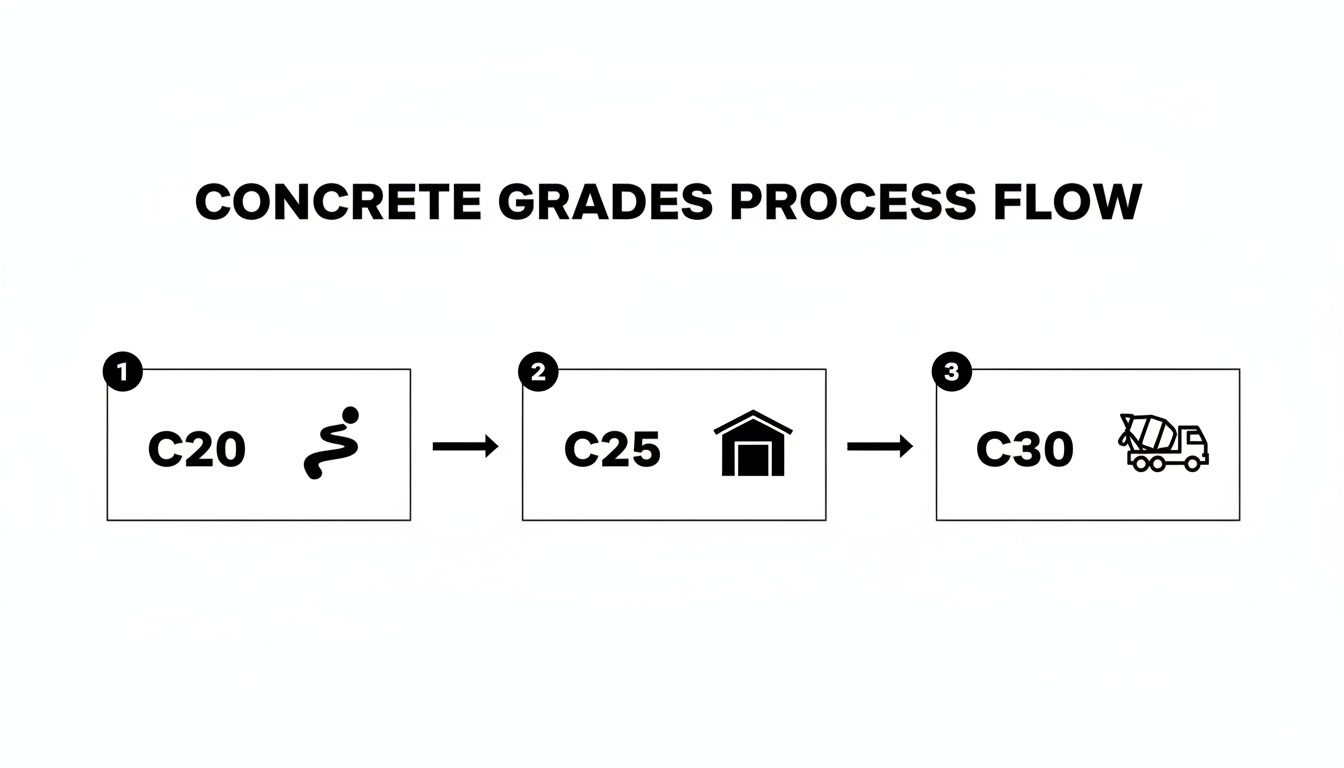

When calculating a concrete mix, you will hear terms like C20, C25, or C30. These are British Standards that define the concrete’s strength and its suitable uses. Understanding these grades is the first step to making sure your project is built to last.

The ‘C’ stands for ‘compressive,’ and the number is the concrete’s minimum strength in newtons per square millimetre (N/mm²) after it has cured for 28 days. This is the standard measure for how much load the concrete can take.

Making the right choice is about engineering a surface that is perfect for its job. Using a C20 mix for a lorry park would be a costly mistake, just as using C40 for a simple garden path is a waste of money.

To help you get it right first time, here is a quick guide to the most common mix ratios used on UK sites.

Common UK Concrete Mix Ratios And Their Uses

This table helps you quickly match a concrete mix ratio to its strength and typical use.

| Mix Grade (BS 8500) | Typical Ratio (Cement:Sand:Aggregate) | Compressive Strength (N/mm²) | Common Applications |

|---|---|---|---|

| C20 | 1:2:4 | 20 N/mm² | Garden paths, shed bases, patio slabs, fence posts |

| C25 | 1:1.5:3 | 25 N/mm² | House foundations, garage floors, internal floor slabs |

| C30 | Prescribed Mix | 30 N/mm² | Commercial yards, driveways, pavements |

| C35 | Prescribed Mix | 35 N/mm² | Heavy-duty industrial slabs, farmyards, roadways |

This table gives you a solid starting point for most projects.

C20: The Choice for Domestic Projects

A C20 mix is your general-purpose concrete. It is perfect for most domestic jobs where you do not need huge structural strength. Think garden paths, shed bases, and patio slabs.

The classic recipe for a C20 mix is 1:2:4—one part cement, two parts sand, and four parts aggregate. This gives you a concrete with a strength of 20 N/mm². It is easy to work with and tough enough for foot traffic and lightweight structures.

C25: The Reliable Choice for Foundations

When you move up to structural work, C25 is the industry standard. It offers a big boost in strength, making it the right choice for house foundations, garage floors, and internal floor slabs that need to carry weight.

With a typical ratio of 1:1.5:3, a C25 mix reaches a strength of 25 N/mm². This creates a strong base that can handle building loads and moderate vehicle traffic. It is the workhorse mix for most groundwork specialists.

The right mix is not just about strength; it is about precision. A well-calculated C25 mix is the backbone of many successful builds. It provides the necessary strength without wasting materials.

C30 and C35: Built for Heavy-Duty Use

When the job demands serious durability, you will need C30 or C35 mixes. These are designed for commercial sites and areas with heavy, constant traffic. This includes commercial yards, farmyards, industrial slabs, and roads that need to stand up to HGVs and heavy machinery.

A C30 grade is a prescribed mix. It demands a precise composition of around 350kg of cement per cubic metre, mixed with 1,800kg of aggregates and 180 litres of water. According to BS EN 206 standards, even a slight increase of cement by 5% can boost strength by 10-15% after 28 days.

Beyond these standard mixes, you can find many various concrete mix types from suppliers.

Choosing the right grade ensures your project meets regulations and performs as it should for years. With this knowledge, you can now calculate the exact quantities of materials you will need.

Calculating Your Material Quantities By Volume And Weight

Once you have picked the right mix ratio, the next step is to turn those numbers into a list of cement, sand, and aggregate. This is where theory meets practice. Getting this calculation right separates a smooth project from one with last-minute trips to the builder’s merchant.

There are two main ways to do it: calculating by volume or by weight. Each has its place. Volume is fine for quick, smaller jobs, but for anything structural, weight is the only way to guarantee precision.

The Volume Method for Quick Mixing

Calculating by volume is the traditional method for smaller sites. It is practical and does not need any special equipment. All you need is a consistent measure—a shovel or a bucket—to portion everything out.

For instance, a 1:2:4 mix is simple: for every one bucket of cement, you add two buckets of sand and four of aggregate. The key rule here is consistency. As long as your measure stays the same for each ingredient, you will maintain the right proportions. This method works well for jobs like setting fence posts or pouring a small patio base.

However, the volume method is not perfect. The amount of sand in a bucket can vary depending on how damp or packed it is. This can create differences in the final mix, which is why we switch to a more accurate method for bigger projects.

The Weight Method for Precision

When you need a concrete mix that is consistently strong, calculating by weight is the professional standard. It removes the guesswork of volume by using the bulk density of each material. This is the best way for any structural work, like foundations, where hitting a specific strength is essential.

To start, you will need the dry bulk densities of your materials. These are good figures to work with:

- Cement: Around 1,440 kg/m³

- Sand (Fine Aggregate): Around 1,600 kg/m³

- Gravel (Coarse Aggregate): Around 1,500 kg/m³

These numbers help turn a simple ratio into a precise list of materials in kilograms.

Worked Example: Shed Base (C25 Mix)

Let’s walk through a real-world example: calculating the materials for a new shed base.

- Project: Shed Base

- Dimensions: 5 metres (Length) x 3 metres (Width) x 0.15 metres (Depth)

- Chosen Mix: C25 (Ratio 1:1.5:3)

First, calculate the total volume of concrete:

Volume = Length x Width x Depth

Volume = 5m x 3m x 0.15m = 2.25 cubic metres (m³)

Next, always account for waste.

It is good practice to add extra for waste and spillage—usually 5-10%. We will add 10% to be safe.

Total Volume = 2.25 m³ x 1.10 = 2.475 m³

Now, we convert our 1:1.5:3 ratio into weights. The sum of the ratio parts is 1 + 1.5 + 3 = 5.5.

To find the weight of each component, we take the total weight of one cubic metre of dry concrete materials (roughly 2,200 kg), divide it by the sum of the ratio parts (5.5), and then multiply that by each individual ratio part.

Here is the breakdown for one cubic metre of C25 concrete:

- Cement: (2200 kg / 5.5) x 1 = 400 kg

- Sand: (2200 kg / 5.5) x 1.5 = 600 kg

- Aggregate: (2200 kg / 5.5) x 3 = 1,200 kg

Finally, let’s get the total materials needed for our 2.475 m³ shed base:

- Cement: 400 kg/m³ x 2.475 m³ = 990 kg

- Sand: 600 kg/m³ x 2.475 m³ = 1,485 kg

- Aggregate: 1,200 kg/m³ x 2.475 m³ = 2,970 kg

To work out how many 25kg bags of cement to order, divide the total cement weight by 25:

990 kg / 25 kg/bag = 39.6 bags. So, you would order 40 bags.

This process gives you precise quantities to order from your supplier. If you want to learn more, read about how to figure how much concrete you need in our guide.

For smaller jobs using pre-packaged mixes, getting quantities right is still important. You can check out a guide and calculator for estimating Quikrete quantities for those products. However, when you are mixing on-site with hired plant machinery, mastering these weight-based calculations is key to quality and cost control.

The Water-Cement Ratio: The Key to Strength

Once your dry materials are sorted, it is time to focus on the most critical ingredient: water. The relationship between water and cement, known as the water-cement (w/c) ratio, is the biggest factor in your concrete’s final strength.

Simply put, the w/c ratio is the weight of water divided by the weight of cement. It is a delicate balance. Too much water creates a weak mix that is easy to pour but results in brittle concrete. Too little water makes the concrete stiff and unworkable.

This is where experience and quality equipment matter. A well-maintained concrete mixer from a reliable hire company like Aylsham Plant Hire ensures every ingredient is blended properly, giving you better control.

Finding the Right Balance

For most construction work, the ideal w/c ratio is between 0.45 and 0.55. This range provides enough water for the chemical reaction of hydration to happen, while making sure the finished concrete is dense and strong.

Let’s look at what that means. For a standard 25kg bag of cement, you would need:

- For a 0.45 w/c ratio: 25 kg x 0.45 = 11.25 litres of water

- For a 0.55 w/c ratio: 25 kg x 0.55 = 13.75 litres of water

That small difference of two litres can have a huge impact on the concrete’s final strength.

Remember, every drop of water beyond what is needed for hydration reduces the concrete’s strength. Aiming for a lower w/c ratio will produce stronger concrete, as long as it stays workable.

Adjusting for Site Conditions

You also need to adapt to what is happening on site. One of the biggest variables is the moisture already in your aggregates.

Sand and gravel can hold a lot of water. If your sand is damp, it might contain 5-7% moisture by weight. Adding your full water amount to wet sand will push your w/c ratio too high and weaken the mix.

Here are a few practical tips:

- Start with less water: Always begin by adding about 80% of your calculated water. Mix it well, then slowly add more until you reach the right consistency.

- Check the texture: A good mix should look like thick porridge. It should slide off a shovel cleanly without being runny.

- Protect your aggregates: If possible, keep your sand and gravel covered to shield them from rain. This helps maintain a more consistent moisture content.

Mastering the water-cement ratio is a mix of science and skill. It is about starting with the correct numbers and using your judgement on the day to fine-tune the mix.

On-Site Tips for Mixing and Pouring

Once your calculations are done, the real work begins. Moving from paper to the site is where smart planning for materials and plant machinery hire can save you time and money.

The first rule is to never order the exact amount of concrete you think you need. Uneven ground, spillages, and small changes in your formwork will always use up some of your volume. That is why a sensible wastage allowance is essential.

For most jobs, adding a 5-10% buffer to your final concrete volume is standard practice. It is a small extra cost that ensures you do not run short at a critical moment.

Adding a Sensible Wastage Allowance

Imagine running out of concrete just before finishing a foundation pour. The cost of a small, last-minute delivery is huge, and the delay can weaken the pour. Suddenly, that extra 10% you ordered looks like a very wise investment.

For a 5m³ pour, a 10% allowance means ordering an extra 0.5m³. It is a small upfront cost that prevents a much bigger headache later on.

On-Site Mixing vs Ready-Mix Concrete

One big decision is whether to mix concrete on site with hired machinery or get it delivered ready-mixed. The right choice depends on the job size, site access, and your needs.

Mixing on site gives you total control. You can make fresh concrete exactly when you need it. This is perfect for smaller jobs or sites with tricky access where a large concrete lorry cannot get in.

On the other hand, ready-mix is best for big pours where consistency and speed are vital. A volumetric lorry can deliver cubic metres of perfectly mixed concrete much faster than a site mixer.

Here is a simple comparison to help you decide.

On-Site Mixing Vs Ready-Mix Concrete

| Factor | On-Site Mixing | Ready-Mix Concrete |

|---|---|---|

| Control & Flexibility | Total control over the mix and timing. Mix what you need, when you need it. | Limited flexibility. You must be ready when the lorry arrives. |

| Cost | Often cheaper for small volumes (under 2m³). | More cost-effective for larger pours due to bulk material prices. |

| Site Access | Excellent for tight spots using a dumper and mixer. | Needs good, solid access for a heavy lorry. |

| Labour | Labour-intensive, needing a team to load and operate the mixer. | Minimal labour needed for the pour, freeing up your team. |

| Consistency | Can vary between batches if you are not careful. | Guaranteed consistent mix strength and quality. |

| Waste | Minimal waste, as you only mix what is needed. | You pay for what you order, even if you do not use it all. |

Coordinating Your Plant Hire for a Smooth Job

If you decide to mix on site, efficiency is everything. The key is to coordinate your plant machinery and material deliveries. There is nothing worse than having a mixer and dumper sitting idle while you wait for a delivery.

Good contractors plan their logistics carefully. This means scheduling your dumper and concrete mixer delivery to match the arrival of your cement, sand, and aggregate.

A well-run site is like a well-oiled machine. The goal is to have the mixer turning the moment materials land. Get your dumper ready to feed the mixer, and have your team ready to place the concrete. This reduces downtime and boosts productivity.

This logistical thinking is vital for any successful job. For example, making sure you have the right foundation work equipment on hand before the concrete arrives is just as crucial as the mix calculation itself. By thinking ahead, you keep the project moving, on time, and within budget.

Common Questions We Hear on Site

Even the best-planned concrete pour can raise questions. Getting the right answers quickly can prevent a costly headache. Here are some common queries we get from contractors.

How Should I Adjust My Mix for the Weather?

The British weather is unpredictable and affects your concrete. In the cold, curing slows down, leaving your pour at risk of frost damage. You can combat this by adding more cement or using an admixture to speed up hydration.

Hot and windy days are the opposite problem. The surface can dry out too fast, leading to cracks. In these conditions, a retarder can slow the set time. Also, always account for moisture in your aggregates—sand left in the rain will need much less water added.

What’s the Difference Between Sharp Sand and Builder’s Sand?

Getting this wrong can seriously weaken your concrete.

For any structural concrete, you need sharp sand. Its larger, angular grains lock together with cement and aggregate to create a strong, dense mix.

Builder’s sand is much finer and has rounded particles. It is perfect for mortar or rendering where you need a smooth finish, but it is a disaster for concrete. Using it in a foundation will give you a weak, crumbly product that is likely to fail.

Can I Keep Mixed Concrete if There’s a Delay?

In short: no. As soon as water hits the cement, the hydration process begins, and the clock is ticking. You have about 60-90 minutes to place and finish the concrete before it becomes unworkable.

Never try to “re-wet” a mix that has started to set. You will destroy its structural strength. This is why getting your timings right for material delivery, plant machinery hire from providers like Aylsham Plant Hire, and your team is so important.

How Much Does a Cubic Metre of Concrete Weigh?

A standard cubic metre of concrete weighs roughly 2,400 kilograms, or 2.4 tonnes. This can vary slightly depending on the mix design and aggregate type.

Knowing this figure is essential for site logistics. It determines the size of dumper you will need and helps you work out if the ground can support a fully loaded ready-mix truck. It is a simple but vital piece of data for planning a safe and efficient pour.

Whether you need a robust dumper to transport materials or a reliable mixer for a perfect on-site pour, Aylsham Plant Solutions has the modern, well-maintained equipment to keep your project on track. Get in touch with our team today for expert advice and dependable plant hire. Learn more at https://aylshamplantsolutions.co.uk.

Related Posts