Getting your concrete order right is a vital first step in keeping a project on budget. If you’ve ever asked yourself, “how do I figure out how much concrete I need?”, you’re already thinking along the right lines.

Order too little, and you face delays and a potential ‘cold joint’ that weakens the structure. Order too much, and you’re literally pouring money down the drain. This guide will give you the confidence to calculate that volume spot on.

Getting Your Concrete Calculation Right First Time

Underestimating your concrete needs is more than just a headache. A short delivery means a frantic call to the plant, hoping they can squeeze in a top-up load. That delay creates a cold joint—where fresh concrete meets already hardened concrete. This can become a serious weak point in a foundation or slab.

On the other hand, over-ordering hits your budget directly. Concrete is expensive, and what you don’t use becomes your problem. Suppliers won’t take it back, leaving you with the cost of getting rid of it. Nailing your concrete estimate is a key part of the bigger picture, as explained in this a professional guide to estimating construction costs.

Quick Concrete Volume Estimator for Common Projects

Before you dive into precise calculations, it helps to have a rough idea of the volumes involved. The table below gives you a quick-glance estimate for some common UK projects. Think of it as a starting point to make sure your final numbers are in the right ballpark.

| Project Type | Typical Dimensions (L x W x D) | Estimated Concrete Volume (m³) |

|---|---|---|

| Single Garage Base | 6.0m x 3.0m x 0.15m | 2.7 m³ |

| Garden Shed Base | 3.0m x 2.5m x 0.10m | 0.75 m³ |

| Small Patio Area | 4.0m x 3.0m x 0.10m | 1.2 m³ |

| Driveway (2 cars) | 6.0m x 5.0m x 0.15m | 4.5 m³ |

| House Extension Footings | 20.0m x 0.6m x 1.0m | 12.0 m³ |

The biggest mistake we see is people mixing up their units. Forgetting to convert everything to metres before you start multiplying is a classic error. Mixing up centimetres and metres can leave you ordering ten times too much or ten times too little.

Remember, these are just rough figures. Uneven ground or non-standard depths will change the final amount needed. In the next sections, we’ll walk through the exact formulas for different shapes. This will help you fine-tune your order, avoid costly mistakes, and ensure your project runs smoothly from the moment the concrete lorry arrives.

The Three Core Formulas for Calculating Concrete Volume

Before you order concrete, you need to get your head around some basic maths. Don’t worry, it’s simpler than you think. At the heart of nearly every concrete job are three simple geometric formulas. Whether you’re pouring a square patio slab, long trench footings, or circular piers for a new deck, mastering these calculations is the first and most important step.

Getting these numbers right removes the guesswork. It turns a vague idea into a solid figure—a precise volume in cubic metres (m³) that you can confidently give to your supplier. Honestly, this separates a smooth, on-budget pour from a stressful, expensive day on site.

It all boils down to a simple, repeatable process.

As you can see, the path from planning to pouring always starts with accurate measurements. Get that right, follow it with a careful calculation, and only then are you ready to place your order.

Calculating Volume for Square or Rectangular Slabs

This is the calculation you’ll do most often. It’s for shed bases, driveways, garage floors, and even large industrial slabs. Luckily, the formula is wonderfully straightforward.

The formula is: Length (m) x Width (m) x Depth (m) = Volume (m³)

The biggest trip-up here isn’t the maths, but the units. Always, and I mean always, convert all your measurements to metres before you multiply. A depth of 150mm becomes 0.15m; a width of 60cm becomes 0.6m. Getting this wrong is a classic mistake that can leave you with ten times too much or, even worse, ten times too little concrete.

Worked Example: A New Driveway Slab

You’re putting in a new driveway. Your measurements are:

- Length = 6 metres

- Width = 5 metres

- Depth = 150 millimetres (which is 0.15 metres)

The calculation is: 6m x 5m x 0.15m = 4.5 m³

You’ll need 4.5 cubic metres of concrete for this slab, before adding any for waste.

Calculating Volume for Footings and Trenches

Footings are just long, skinny rectangular slabs buried in the ground. Because of this, you use the exact same formula as for a standard slab, which keeps things nice and simple.

This works for strip foundations for extensions, garden walls, or any other trench you need to fill. Once again, being consistent with your units is what will get you an accurate figure.

Worked Example: A Garden Wall Footing

You’ve dug a trench for the foundations of a new garden wall.

- Total Length of the trench = 20 metres

- Width of the trench = 60 centimetres (which is 0.6 metres)

- Depth of the trench = 1 metre

The calculation is: 20m x 0.6m x 1m = 12.0 m³

That tells you 12.0 cubic metres of concrete is needed to fill the footing trench.

It helps to see where your project fits into the bigger picture. When you calculate your concrete needs, you’re tapping into a huge national supply chain. For context, ready-mixed concrete volumes in the UK recently hit 2.7 million cubic metres in a single quarter, from around 1,000 production sites nationwide. These numbers show why getting your own calculations right and ordering in good time is so critical. You can read the full research about UK concrete industry trends on thisisukconcrete.co.uk.

Calculating Volume for Circular Columns and Piers

Pouring concrete into circular forms—like for fence posts, decking piers, or structural columns—requires a slightly different formula. This one involves the mathematical constant Pi (π), which we’ll round to 3.14159.

The formula is: Pi (π) x Radius² (m) x Height (m) = Volume (m³)

Just remember that the radius is half of the diameter. So, if your column form is 40cm across (the diameter), its radius is 20cm, or 0.2 metres. “Radius squared” (Radius²) just means multiplying the radius by itself (in this case, 0.2m x 0.2m).

Worked Example: A Set of Decking Piers

You need to fill four circular forms to support a raised deck.

- Number of piers = 4

- Diameter of each pier = 40 centimetres (so the radius is 20cm, or 0.2 metres)

- Height (or depth) of each pier = 1.2 metres

First, work out the volume for a single pier:

3.14159 x (0.2m x 0.2m) x 1.2m = 0.15 m³Now, multiply that by the number of piers you have:

0.15 m³ x 4 = 0.6 m³In total, you’ll need 0.6 cubic metres of concrete for all four piers. Once you’ve got these three formulas down, you can confidently work out how much concrete you need for most jobs.

Calculating for Waste, Spillage and Uneven Ground

Getting your basic volume calculation right is a massive step forward, but the job isn’t over. A perfect calculation on paper rarely translates perfectly to a real-world site. The ground is never perfectly level, formwork might shift, and some concrete will always be lost to spillage or left in the lorry’s chute.

This is why professionals always add a waste allowance. Forgetting this crucial step can leave you just short of finishing the job. This leads to costly delays and the risk of a weak cold joint. Thinking ahead about these real-world issues is key when you figure out how much concrete you need.

Determining Your Waste Allowance

The industry standard for a waste allowance is usually between 5% and 10% of your total calculated volume. Where you fall in that range depends on the specifics of your site and the nature of the pour.

A simple, square slab on a well-prepared, compacted base might only need a 5% buffer. However, more complex jobs require more caution. Consider a higher allowance if you’re dealing with:

- Uneven Ground: If your sub-base has high and low spots, the concrete will fill these voids, using more volume than your average depth calculation suggests.

- Complex Formwork: Pouring into intricate shapes with lots of corners increases the chance of small measurement errors and spillage.

- Difficult Access: If concrete needs moving a long way from the lorry using a site dumper, you will lose more material to spills and what gets left behind in the equipment.

Always err on the side of caution. The cost of having a small amount of excess concrete is almost always less than the cost and hassle of ordering a small top-up load, which often comes with hefty part-load charges.

Calculating for Irregular Shapes

Not every job is a perfect square or circle. Many projects, such as L-shaped foundations or curved garden paths, involve irregular shapes. The secret is not a complex new formula, but a simple strategy: divide and conquer.

The trick is to break down the complex area into a series of simple shapes you already know how to calculate—namely rectangles, squares, and circles. By calculating the volume of each smaller section and then adding them all together, you can arrive at a highly accurate total. This approach is fundamental to good practice, as understanding what is groundwork in construction often involves precise site measurement for pours like these.

A Worked Example: An L-Shaped Foundation

Let’s put this into practice. Imagine you’re pouring the foundations for an L-shaped extension. Instead of trying to calculate the “L” shape in one go, simply split it into two separate rectangles.

Let’s call them Rectangle A and Rectangle B.

- Rectangle A:

- Length = 8 metres

- Width = 5 metres

- Depth = 0.15 metres (150mm)

- Volume = 8m x 5m x 0.15m = 6.0 m³

- Rectangle B:

- Length = 4 metres

- Width = 3 metres

- Depth = 0.15 metres (150mm)

- Volume = 4m x 3m x 0.15m = 1.8 m³

Now, just add the two volumes together to get your base total:

Total Base Volume = 6.0 m³ + 1.8 m³ = 7.8 m³

Finally, let’s apply a sensible waste allowance. Given this is a foundation pour, which can have slight variations in trench depth, a 10% allowance is a safe bet.

- Waste Calculation: 7.8 m³ x 0.10 (10%) = 0.78 m³

- Final Order Volume: 7.8 m³ + 0.78 m³ = 8.58 m³

You would then round this up to the nearest quarter of a cubic metre and order 8.75 m³ to be completely sure you have enough to finish the job properly. This methodical approach ensures your concrete order is ready for the reality of the construction site.

Turning Your Calculation into a Concrete Order

You’ve measured everything twice and calculated your final volume. With the waste allowance added, you have the most important number for the next stage. But now what? The next step is turning that figure into a clear, precise order with a ready-mix supplier.

This isn’t just about rattling off a volume over the phone. It’s about specifying the right materials and coordinating the delivery to ensure a smooth, efficient pour. How well you communicate your needs now will directly impact the success of your groundwork.

While finalising your concrete plans, it’s sometimes worth exploring alternatives. For example, discussions like Should I convert my concrete driveway into a pavers driveway? can offer a different perspective on surfacing projects.

Specifying The Right Concrete Mix

Simply ordering “8 cubic metres of concrete” won’t cut it. You need to be specific about the strength and grade required for your project. Concrete mixes are designated by a “C” number (like C20 or C30). This number indicates their compressive strength in newtons per square millimetre (N/mm²) after curing for 28 days.

Here’s a quick rundown of common grades:

- C20/C25: A popular mix for domestic projects. Think patio slabs, shed bases, and non-structural foundations where massive strength isn’t the primary concern.

- C30/C35: Specified more for commercial jobs, reinforced foundations, garage floors, and driveways that need to handle the weight of vehicles.

- C40 and above: Reserved for heavy-duty work—industrial flooring, structural beams, and areas exposed to harsh chemicals or very heavy traffic.

Your structural engineer or building plans should always specify the correct grade. If you’re ever in doubt, don’t guess. Using the wrong mix can compromise the integrity of the entire structure.

Navigating Minimum Loads and Delivery Logistics

Ready-mix suppliers work with large lorries, which typically hold between 6m³ and 8m³ of concrete. Because of this, they often have minimum order quantities. They will also apply extra charges for smaller deliveries that don’t fill the truck.

A “part-load” or “minimum load” charge is a common fee for any order that doesn’t use the lorry’s full capacity. This can make ordering small volumes, like 1m³ or 2m³, surprisingly expensive. For really small jobs, like setting a few fence posts, it’s almost always more cost-effective to buy bagged cement and aggregate and mix it yourself on-site.

For contractors in East Anglia, understanding the local market is crucial. While the UK ready-mixed concrete sector handles huge volumes, recent trends show some significant shifts in supply and demand. This means that advance planning and ordering early are more important than ever to secure your slot, especially for projects across Norfolk and Suffolk.

On-Site Mixing vs Ready-Mix Delivery: A Comparison

Deciding whether to mix your own concrete or have it delivered comes down to volume, quality control, and labour. Here’s a quick comparison to help you choose the right approach.

| Factor | On-Site Mixing | Ready-Mix Delivery |

|---|---|---|

| Best For | Very small jobs (under 1m³) like fence posts or single path repairs. | Projects needing 1.5m³ or more, ensuring consistent quality. |

| Cost | Cheaper for tiny volumes, but labour-intensive. | Cost-effective for larger volumes, but has minimum load charges. |

| Quality | Consistency can vary between batches, risking weak spots. | Batched at a plant for guaranteed strength and consistency. |

| Speed | Slow and physically demanding, tying up labour. | Fast and efficient, allowing a large area to be poured quickly. |

| Equipment | Requires a cement mixer, shovels, and wheelbarrows. | Requires clear site access for the lorry and machinery to move concrete. |

For anything more than a minor repair, ready-mix is almost always the superior choice for consistency and speed. The time and labour saved by having a lorry turn up with perfectly mixed concrete is invaluable on a busy site.

Connecting Your Order to The Right Machinery

A successful pour doesn’t end with the concrete lorry arriving. That’s often where the real challenge begins: getting all that concrete from the lorry to the pour site quickly and safely. Concrete has a limited workable time before it starts to set, so efficiency is everything.

Having the right plant and machinery ready to go is non-negotiable. For sites with tight access or where the pour is far from the road, a site dumper is essential for moving loads. If you’re mixing on-site or need to place materials at height, a telehandler is an invaluable tool.

Coordinating your concrete delivery with your machinery hire is a critical part of good project management. Working with reliable partners who offer timely machinery delivery is key to making sure your concrete pour goes off without a hitch.

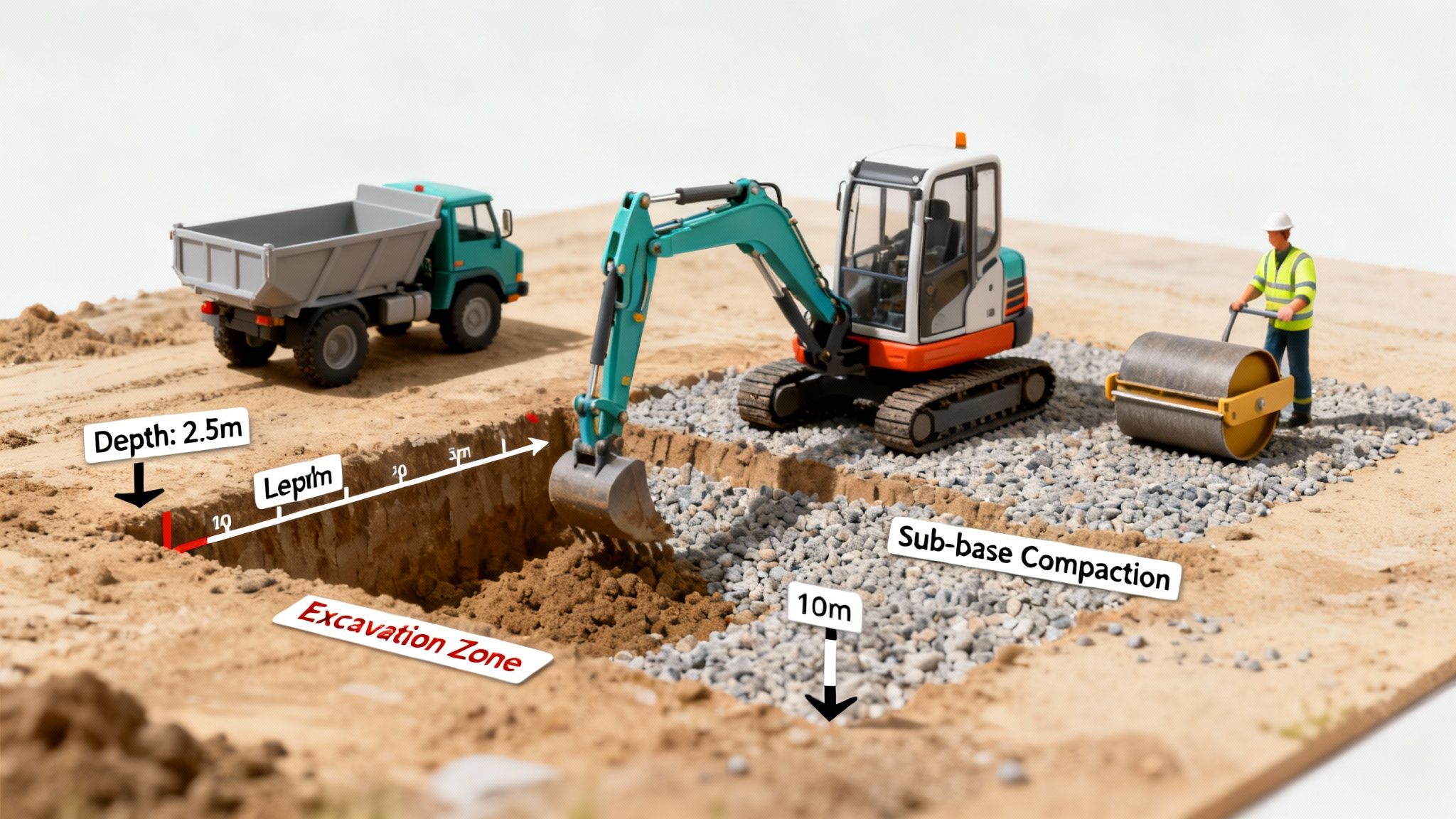

Preparing Your Site with The Right Plant and Machinery

All the careful calculations in the world won’t help if the groundwork isn’t spot on. Before a concrete lorry leaves the plant, the accuracy of your site prep will decide whether your numbers work in the real world. This is where having the right plant and machinery becomes non-negotiable.

When the excavated area perfectly matches your calculated volume, your plan becomes a reality. Good prep work minimises last-minute panics. It confirms the concrete order you place is exactly what the job needs—no costly over-ordering or stressful top-up deliveries.

Excavating to The Exact Depth

The depth of your pour is a critical factor in your volume calculation. Being just a few centimetres out across a large area can throw your figures off dramatically. This is why a mini-digger is invaluable.

Digging foundations by hand is not only back-breaking but also very inaccurate. A mini-digger, with a skilled operator, allows you to excavate to a consistent, precise depth. This accuracy is vital when figuring out how much concrete you need, ensuring the void you create matches the volume you’ve budgeted for.

Moving Materials Efficiently

Groundworks create a huge amount of spoil that needs shifting, and fast. At the same time, you’ll bring in materials for the sub-base, like MOT Type 1 hardcore. For this, a site dumper is the real workhorse.

Relying on wheelbarrows for anything bigger than a small path is a recipe for delays. A dumper moves large quantities of earth or aggregate in a fraction of the time, keeping the project on schedule. Take a look at our solutions for hiring the right plant for your project to see how the right machinery makes all the difference.

Creating A Solid and Level Sub-Base

Once you’ve dug out and the hardcore is in place, the final crucial step is creating a solid, compacted sub-base. A poorly compacted base can settle over time, which is a leading cause of cracks in the finished concrete. This is a job for a roller.

A vibratory roller compacts the aggregate, removing air pockets to create a stable, level foundation. It’s essential for a durable, long-lasting finish. Just as importantly, it ensures your final depth measurement is consistent across the entire area before you pour.

A well-prepared, machine-compacted sub-base is the best insurance you have against your concrete calculations being wrong. It eliminates the guesswork caused by uneven ground and provides a solid, predictable foundation for your pour.

In short, your concrete order is the final piece of the groundwork puzzle. By using the right plant for digging, moving materials, and compaction, you ensure that the hole you dig is the exact size you planned for. This professional approach validates your calculations and sets the stage for a smooth, successful pour.

Common Concrete Calculation Questions Answered

Even with the best formulas and a solid plan, questions always pop up on site. Getting a straight answer is often the last piece of the puzzle you need before you can confidently place your order.

Here are a few of the most frequent queries we get from builders and contractors across Norfolk and Suffolk.

How Do I Calculate for An Area with Varying Depths?

This is a common one, as it’s rare to find perfectly level ground. The simplest approach is to calculate an average depth.

Take measurements at several key points across the area – the corners and the centre are a good start. Add all these depths together, then divide by the number of points you measured. You can then use this average figure in your standard length x width x depth formula.

For ground with more complex slopes, it’s better to split the area into smaller sections. Calculate each one individually and then add the totals together for a more accurate final volume.

What Is The Smallest Amount of Ready-Mix I Can Order?

Most concrete suppliers have a minimum order, which is usually around 0.5m³ to 1m³. However, the real catch is the ‘part-load’ charge they’ll almost certainly apply for any amount below a full lorry load (typically 6m³ to 8m³).

This extra fee can make ordering tiny quantities of ready-mix very expensive. If you’re just setting a single fence post, it’s far more cost-effective to buy bagged cement and aggregate to mix yourself. Always ask a potential supplier about their part-load fees before you commit.

Online calculators are fantastic for a quick estimate in the early planning stages. Use them to double-check your own maths, but never rely on them as the sole basis for an expensive concrete order. Always do your own manual calculations to be certain.

Does The Concrete Mix Type Affect The Volume I Need?

No, the concrete grade or mix type (like C20 or C35) doesn’t change the volume you need to order. A cubic metre is a measure of space; it stays the same regardless of the concrete’s final strength.

The mix specification is vital for the structural integrity of your project, but your volume calculation is a separate job. Figure out the required volume first, then specify the correct mix when you place your order.

Should I Trust An Online Concrete Calculator?

Online calculators are great for getting a rapid, ballpark figure. They provide a useful sanity check for your own calculations and can help you quickly compare volumes for different designs.

However, you should never use one as the final word for your order. These tools can’t account for the unique details of your site, like irregular shapes or uneven ground. They also can’t tell you what waste percentage to add based on site access. Always do your own manual calculations to confirm the numbers before spending any money.

From mini-diggers for precise excavation to dumpers for efficient material handling, having the right machinery ensures your site is perfectly prepared for the concrete delivery. At Aylsham Plant Solutions, we provide reliable, modern plant hire across Norfolk and Suffolk to help you get the job done right. Explore our fleet and get a competitive quote for your next project at https://aylshamplantsolutions.co.uk.

Related Posts

Why Groundwork Contractors Rely on Plant Hire for Every Stage of Construction