Managing demolition waste is one of the biggest challenges on large-scale construction projects. Crusher hire offers an efficient solution when buildings are cleared to make way for redevelopment, processing huge volumes of concrete, brick, stone, and rubble quickly and cost-effectively. Transporting all that material off-site is expensive, time-consuming, and adds unnecessary environmental impact.

That’s where crusher hire becomes a smarter solution for contractors. On-site crushing allows demolition materials to be processed and reused directly on the same project, saving time, reducing costs, and supporting sustainable building practices.

In this article, we’ll explore why crusher hire is the smart choice for contract work and how Aylsham Plant Solutions supports large-scale projects with reliable, high-capacity crushing equipment.

The Growing Need for On-Site Crushing in Commercial Projects

Large redevelopment schemes, like Norwich’s Anglia Square project, generate significant demolition waste. Instead of relying entirely on external waste removal contractors, many project managers now prefer to process as much material as possible on-site. This approach not only saves money but also reduces the need for endless lorry movements through urban areas.

On-site crushing offers several key advantages for commercial sites:

- Reduces haulage costs: Less waste to transport off-site means fewer lorry journeys and lower disposal fees.

- Creates reusable material: Crushed concrete and brick can be repurposed as sub-base for roads, pathways, or foundations within the same development.

- Speeds up clearance: Crushing materials on-site allows sites to be cleared more quickly and efficiently.

- Supports sustainability goals: Recycling reduces the amount of virgin aggregates required, cutting the project’s carbon footprint.

For large contracts, these benefits become even more significant. The bigger the site, the greater the savings.

How Crusher Hire Works on Construction Sites

Hiring a crusher allows contractors to process material at the point of demolition, reducing double-handling and keeping control of waste management entirely in-house.

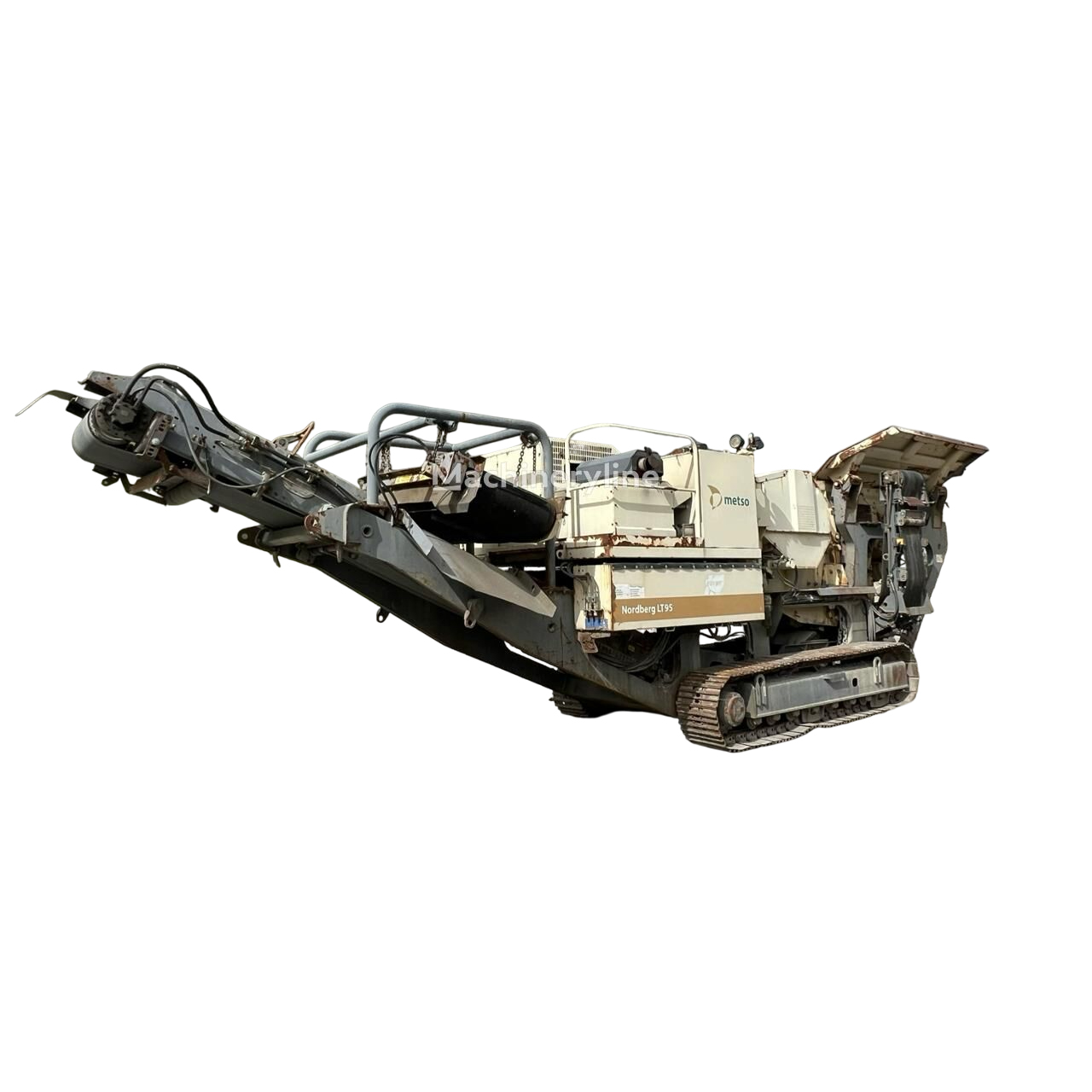

At Aylsham Plant Solutions, our Crusher is delivered directly to site, ready to operate. We offer flexible hire periods to match your project schedule, whether you need the crusher for a few days or several weeks.

The crusher is fed with demolition material using loaders or excavators. As the material passes through, it is broken down into uniform, reusable aggregate sizes. The processed material can then be immediately stockpiled for use elsewhere on site or removed in far smaller volumes.

What Can Be Crushed On-Site?

Modern crushers are designed to handle a variety of materials commonly encountered on demolition sites, including:

- Concrete slabs and blocks

- Brick and masonry

- Stone and hardcore

- Tarmac and asphalt

- Mixed demolition waste

Once processed, this material can be used directly for:

- Site levelling and backfill

- Sub-base for access roads or car parks

- Drainage layers

- Hardstandings or temporary surfaces

By turning waste into usable material, crusher hire transforms a problem into a resource.

The Role of Crushers in Major Demolition Projects

On large-scale schemes like city centre redevelopments or major housing developments, the volume of material generated during demolition can be immense. Traditional clearance methods often involve multiple handling stages:

- Demolish the structure

- Load material into lorries

- Transport to a waste facility

- Pay disposal fees

- Purchase new aggregates for the build phase

Crusher hire simplifies this entire process. With on-site crushing, you eliminate several costly steps, reduce the need for new materials, and streamline your site logistics.

For projects such as the Anglia Square redevelopment in Norwich, where urban space is limited and environmental commitments are closely monitored, crusher hire provides both practical and reputational benefits.

Supporting Other Heavy Plant Operations

Crusher hire often works in tandem with other heavy machinery on major projects. For example:

- 13 to 15 Tonne Excavators load demolition waste directly into the crusher.

- 25 Tonne Dumptrucks transport processed material around the site for reuse.

- Bulldozers spread recycled sub-base material evenly across build platforms.

- Loading Shovels keep stockpiles organised and feeding steady.

This coordinated use of plant allows entire sites to run more efficiently, with minimal double handling and maximum resource reuse.

Health and Safety Benefits of On-Site Crushing

Beyond logistics and cost savings, crusher hire also offers important safety advantages. With less waste material being loaded and transported off-site, there’s a significant reduction in heavy vehicle movements. Fewer lorries entering and leaving busy urban sites lowers the risk of traffic accidents, improves site safety, and reduces disruption to local residents and businesses.

Additionally, on-site crushing keeps material movement contained within the site’s controlled environment, minimising risks linked to external waste handling and potential contamination.

Environmental Advantages of Crusher Hire

On-site crushing also helps reduce the environmental footprint of large construction projects. Every tonne of recycled aggregate produced directly on site means one less tonne of virgin material that needs to be quarried, processed, and transported. This not only conserves natural resources but also reduces the emissions associated with transporting materials to and from the site.

For contractors working on projects with strict environmental targets or planning conditions, crusher hire can make a significant contribution towards meeting sustainability goals. It demonstrates a responsible approach to resource management, which is increasingly important in today’s construction industry.

Why Hire Rather Than Buy?

Many contractors consider whether it’s better to invest in a crusher outright. However, crusher hire offers several benefits over ownership:

- No capital outlay: Avoids major investment in expensive equipment.

- No ongoing maintenance costs: The hire company maintains and services the machine.

- Flexibility: Hire as and when needed, depending on project size and phase.

- Access to modern equipment: Hire providers update their fleets regularly, ensuring you get reliable, efficient machinery.

For most contractors, particularly those working on multiple varied sites, hiring delivers greater flexibility without the long-term financial commitment.

Crusher Hire with Aylsham Plant Solutions

At Aylsham Plant Solutions, we offer reliable, fully maintained crushers ready for immediate deployment on contract work across Norfolk. Our team can advise on the best setup for your site, help coordinate plant deliveries, and ensure your project benefits from efficient on-site waste management.

We understand the demands of large-scale demolition and redevelopment projects, working closely with contractors to match the right equipment to each phase of the job.

Explore our full Plant Hire range or Contact us to discuss crusher hire for your next construction contract.

Related Posts

Why Groundwork Contractors Rely on Plant Hire for Every Stage of Construction